This case study documents Shockey’s recent collaboration with UK-based Pointfuse on the Shihadeh Innovation Center in Winchester, Virginia. The partnership delivered an efficient, precise, and flexible way of converting vast, laser scanner-generated point cloud datasets into segmented mesh models that were quickly used and shared across the entire project team. With these models, team members were able to run clash detection models and optimize their coordination with subcontractors.

The Project: Shihadeh Innovation Center

A joint venture with Winchester Public Schools, Lord Fairfax Community College, and local industry partners, the Shihadeh Innovation Center will be a hub of workforce development for the community – preparing high school students and community members to meet the demands of the regional job market. At Shihadeh Innovation Center, students will receive education in three academies: Professional Skills; Health Sciences; and Science, Technology, Engineering, Arts and Math. The design team was led by Charlottesville-based VMDO Architects. Rehabilitation of the 46,400 SF building began in 2019 and is expected to finish in 2020. By introducing Pointfuse laser scanning software into its existing conditions scanning and VDC workflows, Shockey improved construction sequencing and significantly reduced the project schedule.

The Challenge: Efficient Point Cloud Management

Laser scanning technology is used in construction to capture 3D as-built data for use in scheduling and verification procedures. However, the point cloud datasets produced by laser scanning systems contain literally millions of individual data points. While these point clouds provide exceptional amounts of information to aid the construction process, the IT requirements for managing, processing, and sharing this data can be onerous, especially for projects characterized by large multidisciplinary teams and tight deadlines.

“Laser scanning is used to capture detailed and accurate records during the different build stages,” commented Charles Goin, VDC Manager at Shockey. “Yet the resulting point clouds are often huge, unwieldy raster files that are hard to use,” he added, “and [that] require specialized BIM and VDC software to utilize.” Shockey sought innovations to better deliver as-built information contained in point clouds across their project teams.

The Solution: Convert Large Point Cloud Data into Smaller As-Built Mesh Models

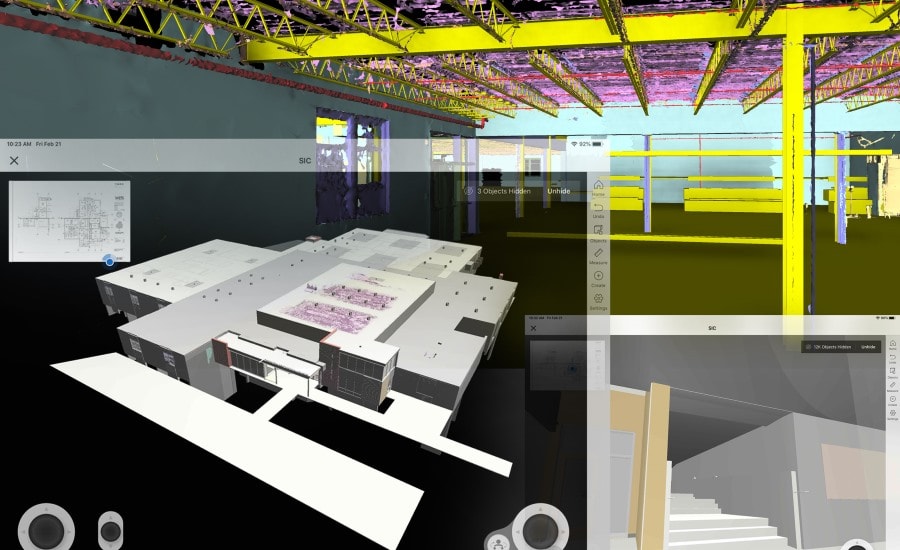

Following demolition work and the removal of suspended ceilings, laser scanning was used to quickly capture existing conditions. The result was a 9GB file composed of 900 million data points and panoramic HDR images. In less than a day, Shockey’s collaborative work with Pointfuse converted the entire point cloud into a manageable, intelligent, classified mesh model that was just a fraction of the digital size of the original.

“Using Pointfuse, we converted the point cloud into a vector cloud-based model and were able to classify major existing systems such as structural and MEP. This process not only improved the usability of the data, but it also reduced the cloud size to under 80MB from 9GB, a factor of over 100,” said Goin.

The team was then able to combine the as-built Pointfuse model with the design model and run clash detection, improving planning with the other trades involved with the project.

Comparison of the Pointfuse model with the original Revit model highlighted areas where the as-builts deviated from the design, allowing the Shockey team to immediately identify additional structural concrete forms, changes in the size and spacing of the joists (impacting architectural treatments and finishes), along with changes in other services such as HVAC, MEP, and fire safety. The updated Pointfuse as-built model was then shared across the entire team via the Procore BIM viewer app on their mobile devices.

While 3D coordination models are typically used on the desktops of VDC personnel, cascading the model throughout the project’s organization brought clarity, empowering specialists in the field to find further ways to save resources and capital even while construction was fully in motion. On this project, for example, sharing as-built information outside of the VDC team enabled the mechanical contractor to see that existing sprinkler mains could be modified and integrated with the new fire safety system, allowing for reuse of existing infrastructure and providing considerable time and cost savings.

The Outcome: VDC Technology Improves Workflow Integration, Speed of Project Delivery

By harnessing the AI of Pointfuse’s software, the project team efficiently converted the data capture of the raw point cloud into an easy to share as-built model that classified building features, aided in clash detection, and improved workflow – all with small, portable files that can be up to 100 times smaller than the original point cloud.

This seamless union of technologies brought transparency and empowerment throughout the project structure, allowing the team to optimize scheduling and identify risks before they happened.

###