This article was initially published by the Winchester Star.

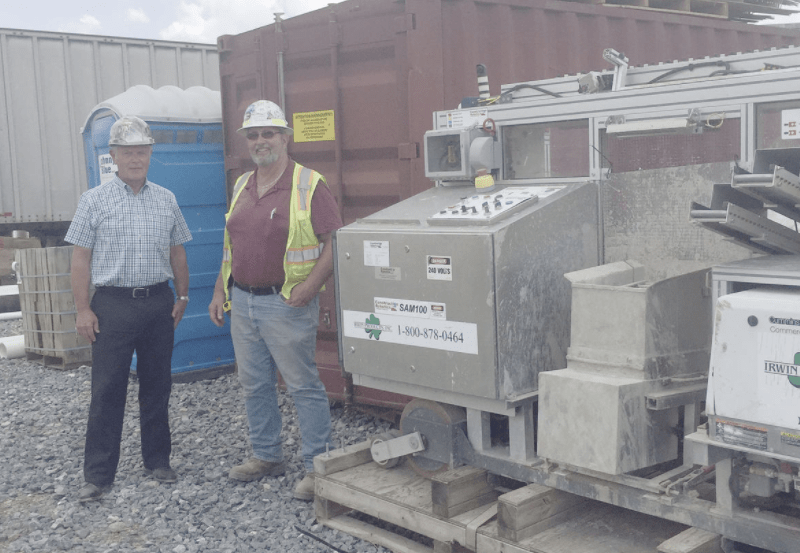

WINCHESTER — Nearly all the brickwork on the outside of the new James R. Wilkins Jr. Athletics & Events Center at Shenandoah University is complete, but it wasn’t laid by a traditional mason. The majority of the brick was laid by a robot named SAM.

SAM, which stands for semi-automated mason, is one of six brick-laying robots in the country. Under optimal conditions he can lay up to 3,000 bricks in a day; a human can do between 600 and 1,000.

Although SAM is faster than a human, he didn’t really replace human labor on the construction site. SAM can’t lay brickwork in corners or at the very top of the structure, so typical masons did that work. “All this does is supplement our needs,” Bill Stynes, executive vice president of JD Long Companies, said.

“There is a shortage of labor everywhere,” said Donnie Werdebaugh, project superintendent from Howard Shockey & Sons Inc.. “This allowed our manpower to be more productive somewhere else on the site.”

JD Long Companies, located in Manassas, was hired as the masonry company for the project. It decided to use SAM as sort of a test to see if it met expectations.

While SAM was working at Shenandoah University, he set a world record for the most bricks laid in an eight-hour period: 3,270.

A total of about 375,000 bricks have been laid on the new events center, by both humans and SAM.

Werdebaugh first heard of brick-laying robots when JD Long approached him about using SAM for the project.

“I thought it really made a lot of sense when I heard about it,” Werdebaugh said.

SAM isn’t a fully independent worker; he still needs four human “tenders” to work with him to make sure he is doing his job correctly. One person feeds the bricks along a conveyor belt for SAM to pick up, one feeds the mortar, one strikes the joint (smoothing the mortar), and one cleans up the bricks after SAM has laid them.

Construction Robotics, a company based in New York, developed SAM and programmed him to lay the bricks at Shenandoah. He uses lasers to make sure he places each brick in its specific location. If there are any imperfections in a brick SAM picks up (such as being too big or too small, or having a chip in a corner), he will detect them, and put it back down. “He can be programmed to lay bricks in any type of pattern,” Stynes added.

According to Stynes, JD Long was pleased with how SAM performed. “SAM came reasonably close to what we expected,” Stynes said. JD Long rented SAM for about $3,000 a week, and he was at the project site for about nine weeks, Stynes said.

Source: Julia Kazar, Winchester Star. See original story here.